Next Generation Platform Design for Higher Speed up to 10 FOV/s The TRI TR7600F3D SII is the next-generation high-speed in-line automated X-ray inspection (AXI) solution, offering speeds up to two to three times faster than the previous model. This advanced AXI system can inspect large boards up to 900 mm x 460 mm, significantly lowering escapes and false calls without compromising the production line's cycle time. With 5 µm high precision, the TR7600F3D SII ensures comprehensive defect detection. Its next-generation mechanical design enables higher speeds, achieving up to 10 fields of view (FOV) per second. The system supports inline fine-tuning for multiple samples without interrupting production, enhancing efficiency and flexibility. Additionally, it is smart factory ready, offering easy MES connectivity to integrate seamlessly into modern production environments. This makes the TR7600F3D SII a leading solution for high-speed, accurate, and reliable inspection in demanding production settings.

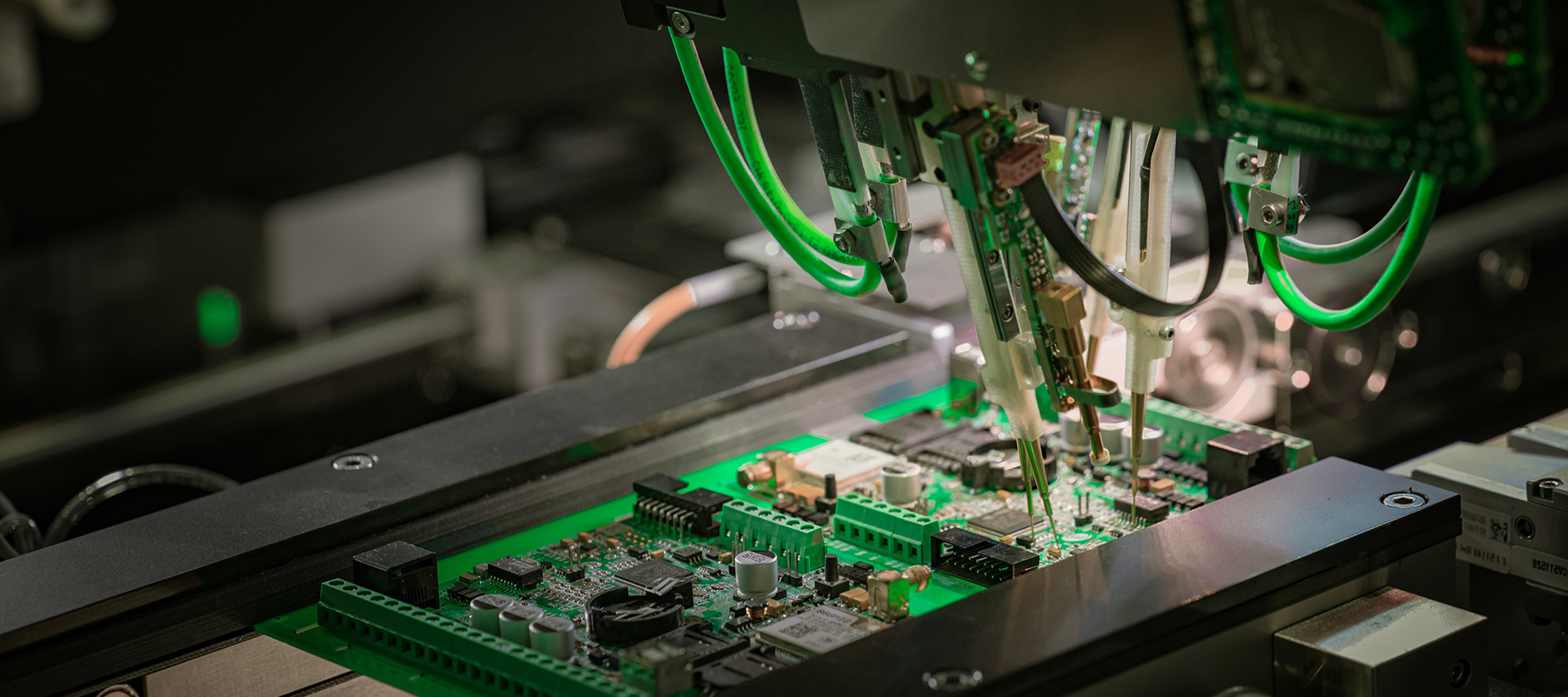

The ASM SIPLACE SX chip mounter stands at the forefront of high-mix electronics production, offering unparalleled flexibility and versatility. With three enhanced placement heads – CP20, CPP, and TWIN – it covers a vast component spectrum, ensuring exceptional reliability even with odd-shaped components. In addition to its advanced placement capabilities, the SIPLACE SX provides a wide array of feeder and conveyor options, further enhancing its adaptability to various production requirements. Its efficient dual conveyor system facilitates the movement of smaller boards measuring up to 450mm by 260mm, while the optional Smart Transport Module enables processing of larger boards up to 1,525mm by 560mm. With its comprehensive features and capabilities, the SIPLACE SX redefines the standards of high-mix electronics production, empowering manufacturers to achieve unparalleled efficiency and quality in their assembly processes.

Meet the SIPLACE TX, revolutionizing the landscape of intelligent manufacturing with its cutting-edge capabilities. Powered by the new Placement Head CP20 and its high-resolution component camera, along with the innovative SIPLACE SmartFeeder Xi, this machine sets new benchmarks in performance. But the SIPLACE TX doesn't stop there. With the introduction of the SIPLACE Tray Unit and two stationary high-end camera systems, it transforms into a compact end-of-line solution, saving valuable space on the factory floor. Its unparalleled flexibility extends to conveyor systems, component feeding, and intelligent software options, offering unmatched versatility. Modular, flexible, and open, the SIPLACE TX seamlessly integrates into ASMPT's open automation concept for the Intelligent Factory. With standard interfaces and a growing range of automation options, it stands as a state-of-the-art performer, catering to the diverse needs of modern electronics production.

Crafted for high-volume applications, the new ASM SIPLACE X S chip mounter is the epitome of performance and reliability. Engineered with robust placement heads and intelligent feeders, it ensures lightning-fast placement while maintaining precision and process reliability through smart sensors and a unique digital vision system. Innovations like rapid and accurate PCB warpage detection further enhance its capabilities. Ideal for demanding applications such as telecommunication/5G and IT/server industries, the SIPLACE X S guarantees non-stop processes, maximum yields, and extreme productivity. With its unparalleled performance and cost-effectiveness, it positions you ahead of the competition, empowering you to meet the most stringent production demands with ease.

The FUJI AIMEX III CHIP MOUNTER is a pinnacle of flexibility and efficiency, designed to accommodate component, PCB, and production variations with ease. Supporting large panels up to 774mm (L) x 710mm (W), it enables diverse manufacturing needs. With its dual conveyor configuration, the AIMEX III facilitates simultaneous production of two different products, optimizing throughput. It offers various production methods and supports a wide range of panel sizes, ensuring adaptability. The DX head allows for seamless tool exchange, catering to part sizes from small chips to large odd-form components. Wide range nozzles further enhance placement efficiency, while dynamic tool exchange during production ensures optimal performance. Through the DynaHead feature, the AIMEX III achieves borderless production by dynamically exchanging between 12-nozzle, 4-nozzle, and single nozzle tools, maximizing efficiency and versatility.

The FUJI AIMEX IIIc chip mounter epitomizes versatility and scalability, serving as an all-in-one solution tailored for high-mix production environments. Engineered to enhance productivity, it boasts a comprehensive set of functions designed to streamline operations, facilitating swift transitions during new production introductions and product model changes. With its flexible support for various production scenarios, the AIMEX IIIc caters to users across diverse sectors, including Electronic Manufacturing Services (EMS), automotive industry, and beyond. Whether adapting to changing market demands or accommodating complex manufacturing requirements, this machine delivers unmatched versatility and efficiency.