The TR7700 SIII Plus represents the latest advancement in TRI's AOI technology, offering precise multi-phase inspection at high speeds. Equipped with an ultra-fast camera, intelligent auto conveyor, and a redesigned user interface, this system provides a robust and user-friendly AOI solution. It facilitates quick programming, efficient board loading, smooth production line integration, and supports offline programming. The system's new color algorithm, along with multiple lighting phases, enhances defect detection and ensures high inspection accuracy with minimal false positives. Key features include high-speed, high-precision multi-phase AOI, an intuitive GUI for easy programming and offline editing, an intelligent auto conveyor that reduces load times, and an advanced color algorithm for improved accuracy and reduced false calls.

The TR7700Q 3D AOI combines the latest 2D and 3D technologies, utilizing digital quad fringe pattern projection to revolutionize PCB assembly inspection. Its versatile programmable 3D digital fringe pattern technology covers a wide inspection range with exceptional accuracy, detecting even the smallest coplanarity defects and solder joint issues. Ensuring the quality of solder joints is achieved through IPC-compliant 3D solder fillet inspection, which checks the fillet shape to detect issues like insufficient solder volume, non-wetting, and dry pads. This system features ultra-high precision 2D+3D stop-and-go AOI, solder height and volume inspection, and accurate quad 3D digital fringe projection. It also boasts an adaptive 3D height range of up to 30 mm and an air-free intelligent conveyor system (IACS), making it a robust solution for comprehensive PCB assembly inspection.

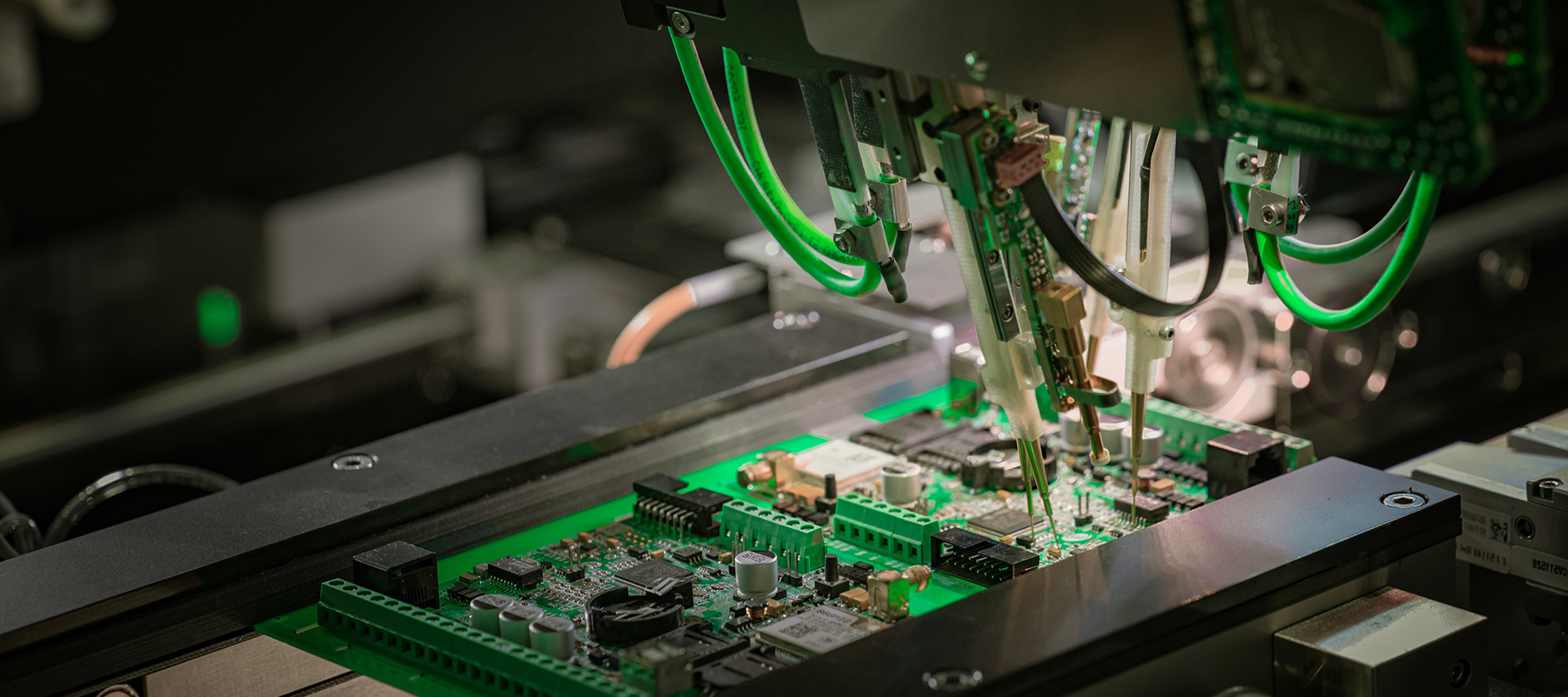

The TR7700QH SII Series represents the latest advancement in ultra-high-speed 3D Automated Optical Inspection (AOI), capable of inspecting at impressive speeds of up to 80 cm² per second while maintaining uncompromised Gauge Repeatability and Reproducibility (R&R). This ensures precise and consistent inspection results, critical for maintaining high-quality standards in manufacturing processes. The TR7700QH SII is powered by TRI's state-of-the-art Smart Programming, cutting-edge AI Algorithms, and advanced Metrology measurement capabilities, all working together to deliver exceptional accuracy and efficiency. These technologies allow for rapid adaptation to various inspection needs, providing a flexible and robust solution for complex production environments. Furthermore, the TR7700QH SII is fully compatible with the latest Smart Factory standards, including IPC-CFX and The Hermes Standard (IPC-HERMES-9852). This compatibility ensures seamless integration with modern manufacturing ecosystems, facilitating enhanced connectivity, data exchange, and process automation. By supporting these standards, the TR7700QH SII not only meets current industry requirements but also helps pave the way for future advancements in intelligent manufacturing and quality control.

The MagicRay 3D AXI-VX2000 machine offers high-speed imaging and multi-angle projection reconstruction, making it ideal for inline non-destructive inspection of SMT, DIP, and IGBT semiconductors. It covers a wide range of components, including BGA/LGA/CSP, SOP/QFP/QFN, transistors, R/C-IGBT, bottom electrodes, power modules, POP, connectors, THT components, and more. Featuring high-speed dynamic imaging, the detection speed of the AXI-VX2000 reaches 1.7 seconds per field of view (FOV). It adaptively applies seven projection styles and seven resolution types to meet various usage scenarios. The machine supports three separate programming styles and offers one-touch value learning functionality, simplifying the setup process. Its XY, YZ, and XZ three-view interface makes diagnosing defects more intuitive. Additionally, dual linear motors with grating rulers ensure precise positioning, enhancing the accuracy and reliability of inspections. Overall, the MagicRay 3D AXI-VX2000 machine combines advanced imaging technology with versatile projection and programming options, making it a powerful solution for comprehensive semiconductor inspection.

High Performance 3D AXI for Large PCB Assemblies The TRI TR7600 SIII series is TRI’s flagship inline line scan 3D AXI system, specifically tailored for the inspection of larger board sizes, up to 1200 mm x 660 mm. Designed for high performance 3D AXI for large PCB assemblies, this series offers the fastest high-resolution imaging performance and superior image quality in the industry’s most advanced automatic X-ray inspection. Equipped with new 3D AXI intuitive software, the TR7600 SIII series simplifies the setup of inspection programs based on CAD data. The system includes TRI’s extensive smart component library, reducing the engineer's workload and minimizing production downtime. Enhanced 3D inspection with planar CT imaging can recreate a complete 3D model of each solder joint, enabling clear analysis of shape irregularities, head-in-pillow defects, and voiding problems. Vertical cross-section CT images assist with reliable visual reviews of borderline and buried solder joints. Delivering ultra-high-speed 3D CT X-ray inspection with excellent image quality, the TR7600 SIII series features a true 3D solder joint viewer that provides high resolution for inspecting even the smallest components, such as 01005 inch chips. This ensures thorough and accurate inspection of large PCB assemblies, making it a leading solution in the industry.

The TRI TR7600F2D is engineered for high-performance inline 2.5D AXI, particularly suited for single-layer PCB and FPCB assemblies requiring exceptional image clarity. This system is ideal for mobile electronics, as it can effectively identify minute voids, 01005 solder defects, and various QFN and BGA issues. By integrating fully automated programming with multi-resolution capabilities, it optimizes production yields efficiently. Designed for ultra-high-resolution inspection, the TR7600F2D covers areas up to 900 mm x 460 mm and significantly reduces engineer workload through automated setup processes. Its advanced processing and multi-resolution options guarantee superior image quality. The system also employs 2D and off-axis imaging to provide shadow-free inspection, with an X-ray tube adjustable up to 130 kV/300 µA. These features collectively make the TR7600F2D a premier solution for ensuring the highest standards in mobile electronics production.