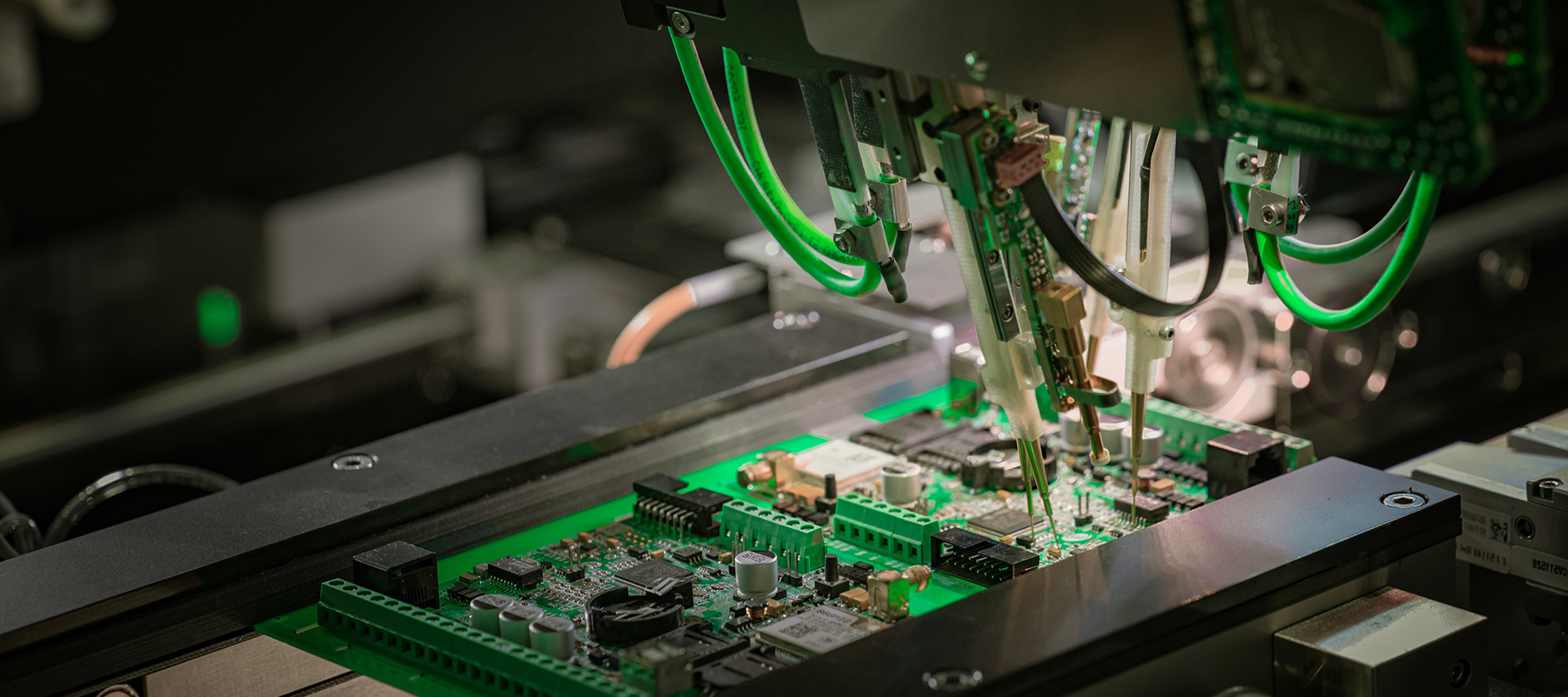

With industry-leading speeds of up to 200 cm²/sec, the TRI TR7007 SII Plus stands out as the ideal SPI solution for any production line. This highly accurate, inline, shadow-free solder paste inspection system offers full 3D inspection at resolutions of 15 µm or 10 µm. Built on a high-precision, reliable linear motor platform, the system's key features include a closed-loop function, enhanced 2D imaging, auto-warp compensation, and fringe pattern technology. TRI's quick and intuitive user interface simplifies programming, delivering maximum value to your production. The TR7007 SII Plus provides a highly accurate, shadow-free SPI solution with class-leading inspection performance. Its easy programming maximizes production line value. With unmatched speed and throughput, TRI’s Dynamic Imaging technology ensures the inspection process keeps pace with the production line without slowing down, even for complex boards with multiple local fiducial marks. This unique solution guarantees perfect results while reducing costly cycle times. The TR7007 SII Plus is fully optimized for stability, delivering reliable inspection results 24/7 and automatically compensating for manufacturing tolerances and board warp. It features the world's first inspection capability for low solder paste bridges under 30 µm, ensuring no printing defects are missed and guaranteeing accurate results under any conditions. With its dual projection design and intelligent software, the TR7007 SII Plus ensures completely shadow-free inspection results and eliminates issues with specular reflections, providing unparalleled inspection accuracy and reliability.

The TRI TR7007 SIII operates at an industry-leading speed of up to 170 cm²/sec. Built on an enhanced mechanical platform, it guarantees stability, accuracy, and precision during inspections. This 3D SPI is an Industry 4.0 Ready Solution, supporting advanced protocols such as IPC Connected Factory Exchange (CFX) and IPC Hermes 9852 standard. The TR7700 SIII 3D AOI combines cutting-edge 2D and 3D technologies with next-generation software, revolutionizing PCB assembly inspection. With complete coverage at full speed, the TR7700 SIII uses an ultra-high-speed color camera and true 3D profile measurement to thoroughly inspect even complex automotive and smartphone assemblies. Its inspection range covers everything from basic SMT components to large thru-hole capacitors, switches, connectors, and hidden joints. Equipped with a highly accurate laser sensor, the TR7700 SIII surpasses other 3D technology boundaries. It can inspect components up to 20 mm high with maximum precision. The use of laser light eliminates issues with black or mirror-like components on low contrast backgrounds. Interactive 3D models help operators quickly review defects, such as lifted BGA components, IC leads, connectors, switches, and other mounted devices, enhancing post-reflow inspection.

The TRI TR7007Q SII is a cutting-edge 3D SPI system designed to enhance your production processes. With its high-speed platform, this 3D SPI delivers inspections up to 50% faster compared to previous models, ensuring optimal efficiency. Experience improved accuracy and stability, which allows for precise solder measurements and minimizes false calls. Equipped with a wide spectrum light system and optional coaxial lighting, the TR7007Q SII enhances contrast and detection rates, enabling you to capture intricate details with exceptional clarity. As an Industry 4.0 Ready Solution, it supports advanced protocols such as IPC Connected Factory Exchange (CFX) and IPC Hermes 9852 standard. This advanced system features a wide spectrum light for enhanced contrast and detection rate, improving accuracy and stability for precise solder measurements. A new motion controller, EtherCAT, facilitates real-time measurements. The TR7007Q SII also boasts 100% shadow-free quad/dual digital fringe projectors and SmartWarp compensation to eliminate local PCB deformation. As a smart factory solution, it offers real-time SPC trends and is closed-loop ready with feedback and feed-forward capabilities, ensuring comprehensive and efficient production line management.