With over 15 years of industry experience, our commitment to innovation and precision goes beyond offering cutting-edge solutions – we prioritize your satisfaction.

This stack destacker is specifically designed for PCB assembly, serving as a bare board loader that places boards onto the SMT production line. It is capable of handling a wide range of PCB sizes, from as small as L50 x W50mm to as large as L330 x W250mm, and in another configuration, from L50 x W50mm to L530 x W460mm. The device supports PCBs with a thickness ranging from 0.5mm to 5mm, making it versatile for different board specifications. The conveyor height is adjustable to 910±20mm, ensuring compatibility with various production setups. The conveyor direction is flexible, allowing for operation from left to right or right to left, depending on the specific requirements of the production line. This adaptability helps streamline the integration process into existing SMT lines. Furthermore, the stack destacker boasts an impressive cycle time of less than 6 seconds, enhancing the efficiency of the loading process and contributing to overall higher productivity in PCB assembly operations.

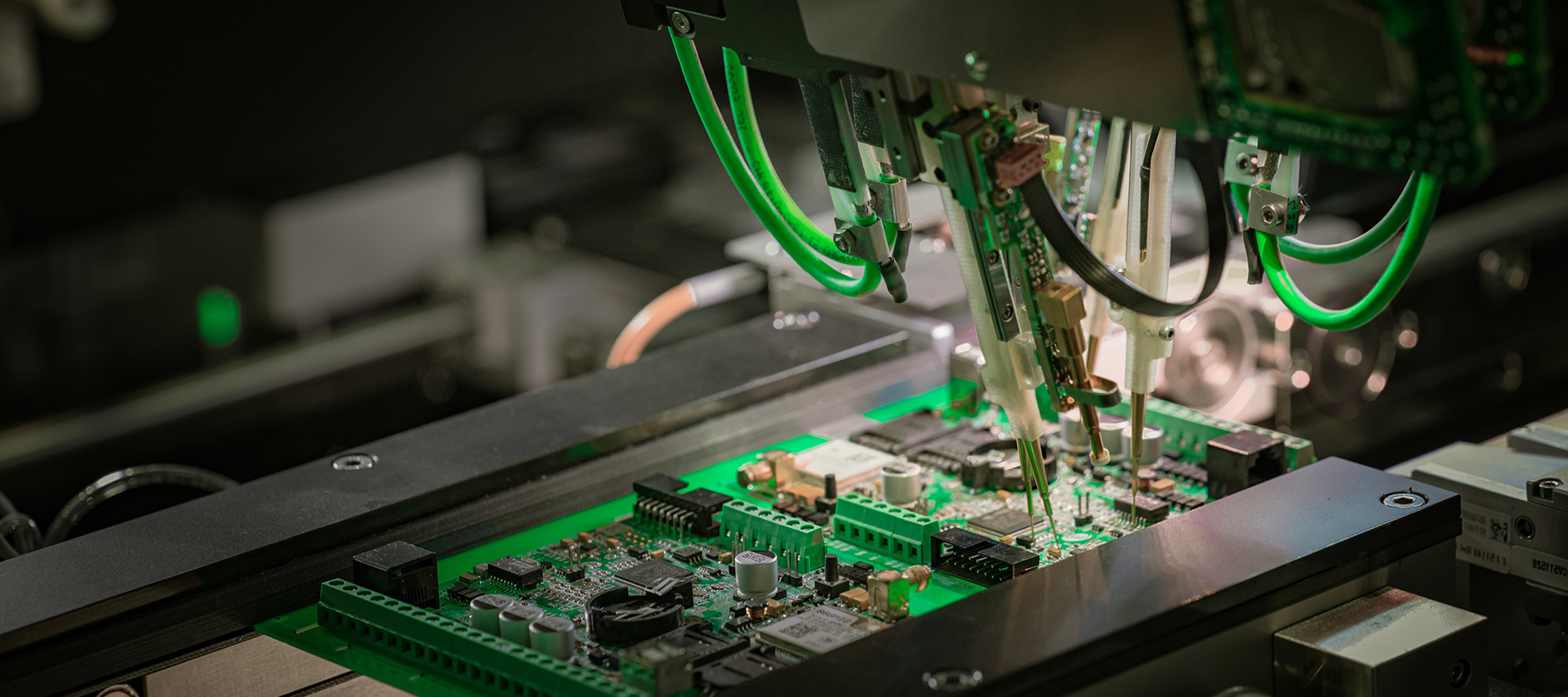

The vacuum loader is utilized for loading bare boards onto SMT production lines. It functions by lifting the top PCB from the stack and placing it onto a belt segment. The vacuum loader is easy to operate, featuring a touch screen controller for intuitive user interaction. It is equipped with a Panasonic PLC control system, ensuring precise and reliable performance. This machine supports both suction and sending board functions, providing versatility in handling PCBs. The loader offers four selectable pinches of 10, 20, 30, and 40mm, accommodating various PCB sizes. Its structure is fully enclosed, ensuring a high level of operational safety. Additionally, it features parallel and smooth width adjustment, allowing for consistent and accurate PCB handling across different production requirements.

Within a PCB assembly line, the SMT telescopic conveyor offers a "normal open" passage. A conveyor segment integrated into it slides across the opening to deliver PCBs to downstream units. This equipment is particularly useful for SMT production lines that are too long and require a convenient midpoint access. The track is telescopic and easy to operate, allowing for flexible integration into various production setups. Its ergonomic design reduces arm fatigue, making it more comfortable for operators to use over extended periods. The conveyor utilizes a servo telescopic mechanism, where the torque can be adjusted to prevent injury and ensure safe operation. The folding cycle time is short, facilitating quick and easy passage for personnel. Additionally, there is a one-touch lifting button at both ends of the conveyor, making it simple and convenient to operate.

The SMT Shuttle Conveyor is utilized for transporting boards from one line into two lines, or vice versa, without altering the orientation of the board during traversing. This conveyor features a PLC control system, ensuring reliable and precise operation. It includes a smart system with one-key width adjustment and remote fault monitoring, enhancing convenience and operational efficiency. The buffer deceleration design allows for smoother and more accurate transitions of the PCBs. The width of the PCB board can be adjusted conveniently and accurately using a screw adjustment mechanism. Additionally, the shuttle conveyor is equipped with a standard SMEMA interface, enabling easy integration with other equipment on the production line.

Used for good/bad PCB separation or visual inspection without interrupting the PCB flow. It supports up to 5 PCB floors with 25mm spacing.