Papua New Guinea Zenith

Category:

Papua New GuineaZenith

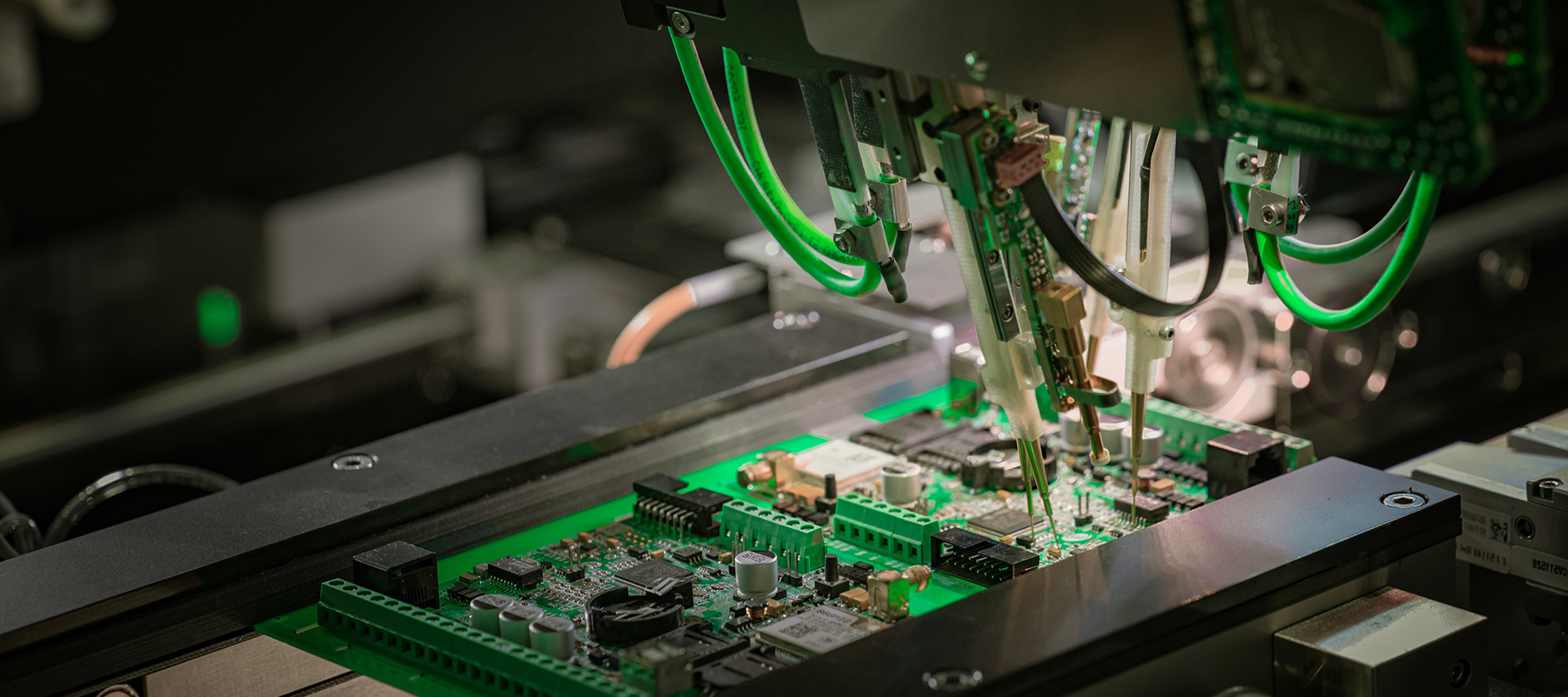

Product Description

| Model | Koh Young Zenith |

| Inspection Performance | |

| Inspection Speed | 25cm2/Sec |

| Height Accuracy | 2μm |

| Cameral Pixel Resolution | 20μm |

| Cameral | 4MPix |

| FOV Size | 47mm x 35mm |

| PCB Handling | |

| Conveyor Width Adjustment | Automatic |

| PCB Thickness | 0.4-5mm |

| Max. PCB Size | 330*250mm(M); 510*510mm(L); 690*610mm(XL) |

| Max. PCB Weight | 3.0Kg(M); 5.0Kg(L); 6.0Kg(XL) |

| Installation Specification | |

| Machine Weight | 600Kg(M); 900Kg(L); 1000Kg(XL) |

| Machine Size | 1000*1230*1684mm(M) 1200*1520*1684mm(L) 1300*1580*1684mm(XL) |

| Side Clearance(Top/Bottom) | 50mm |

| Electric Supply | 200-240VAC, 50/60HZ Single Phase |

| Air Supply | 0.45Mpa |

: next page

Need help to find the right solution with our experts?

CONTACT

Address: Room 301, Building 12, No. 2 Fumin Middle Road, Dalang Town,Dongguan, Guangdong Province 523770, China.

Email: info@seiki-hk.com

Tel: +86 19917563620

Follow

Scan attention consultation

Privacy Policy SEO Citysite Support: 300.cn Dongguan

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.