U.S.A Destacker

Category:

U.S.ADestacker

Product Description

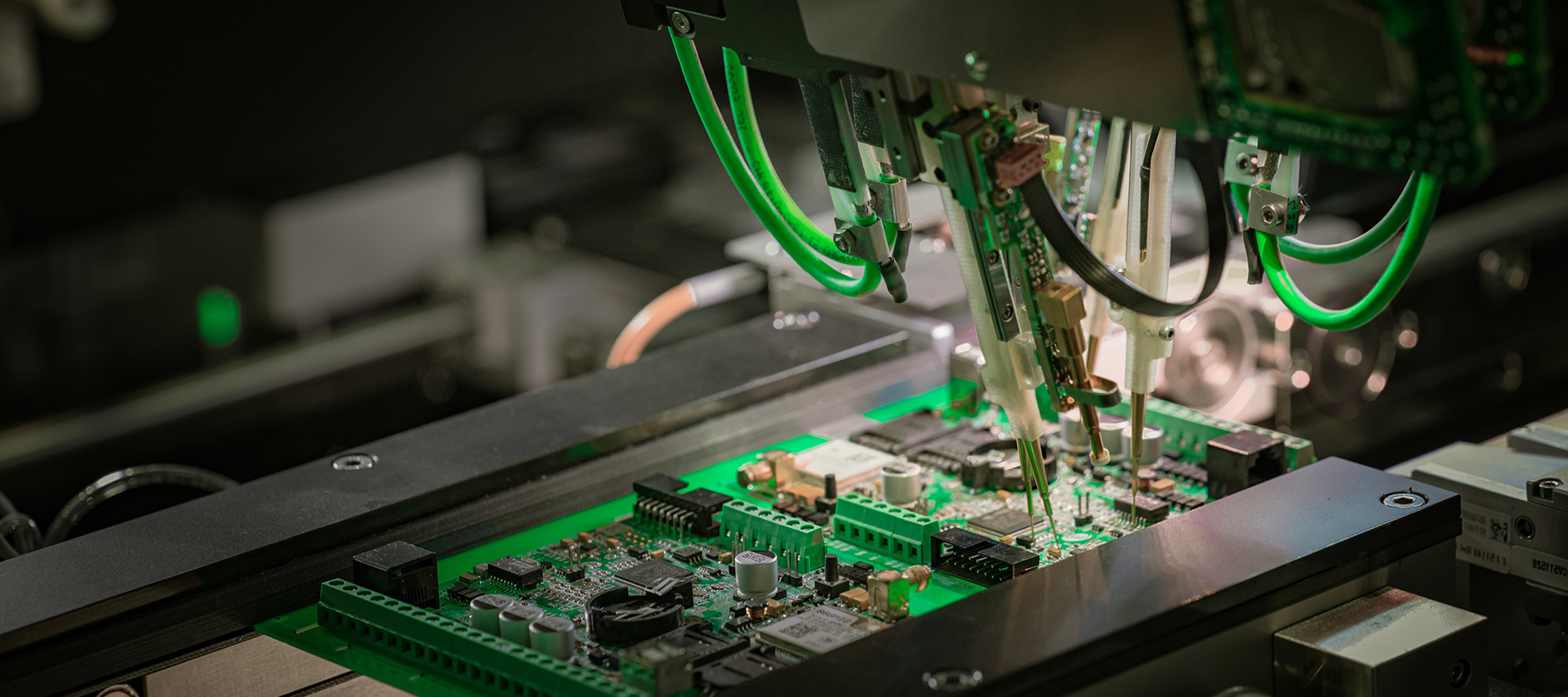

The best Stack Destacker is an efficient device designed for the PCB assembly process. It is mainly used to separate the stacked circuit boards one by one and feed them into the SMT (surface mount technology) production line as a loader for bare boards. This equipment plays a vital role in the electronics manufacturing industry and can significantly improve the level of production automation and work efficiency.

This separator has excellent adaptability and flexibility and can handle PCB boards of different sizes and thicknesses. By adopting a precise mechanical structure and advanced separation technology, the equipment can ensure the smooth separation of the circuit boards to avoid scratches or damage. In addition, its operation is simple and easy to understand, and the touchscreen interface supports multiple language settings, which is convenient for factory technicians to get started quickly. Some models also support linkage with other equipment through the SMEMA interface to ensure the smooth operation of the entire production line.

To meet the high-quality requirements of the electronics manufacturing industry, the best Stack Destacker adopts high-strength materials and modular design, with high durability and low maintenance costs. The built-in intelligent detection system can monitor the operating status in real-time. If an abnormality is found, it can automatically shut down and issue an alarm to ensure production safety. Whether in mass production or small batch customized processing, this stacking and separation machine can provide stable and reliable performance and is an indispensable automation solution in SMT production lines.

Specification

| Model | DS250 Destacker | DS460 Destacker |

| PCB Handling | ||

| PCB Size | L50 x W50mm - L330 x W250mm | L50 x W50mm - L530 x W460mm |

| PCB thickness | 0.5-5mm | |

| Conveyor height | 910±20mm | |

| Conveyor direction | Left to right or right to left | |

| Cycle time | <6s | |

| Conveyor belt | <3mm flat belt | |

| Conveyer Width Adjustment | Manual | |

| Equipment Specification | ||

| Dimension | L600*W725*H1,425mm | L600*W960*H1,425mm |

| Power supply | 110V/60Hz & 220V/50Hz | |

| Working mode | Stack board or straight through | |

| Control system | PLC+Touch screen | |

| Shape of conveyor | L | |

| Operation table | Single | |

| Interface | SMEMA | |

: next page