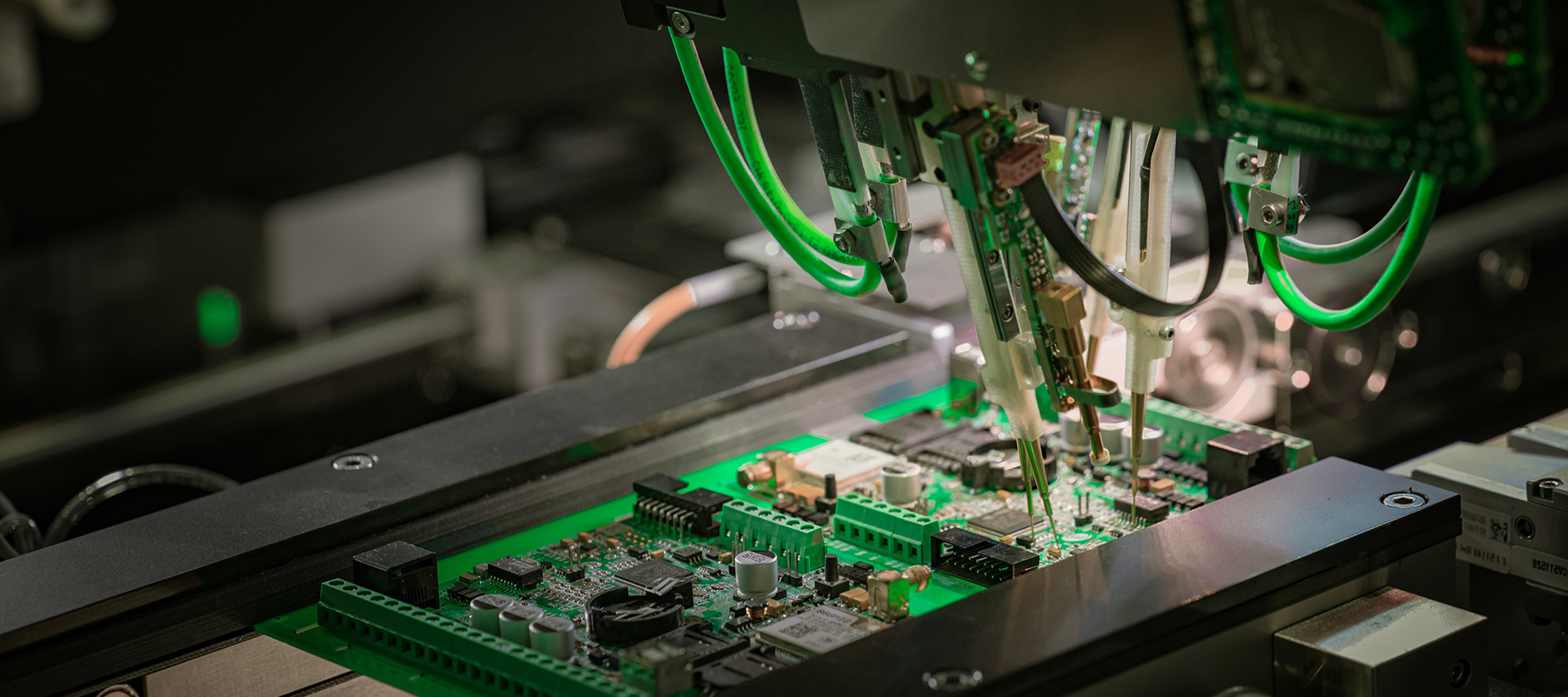

U.S.A 3Di Series

Category:

U.S.A3Di Series

Product Description

Advantages of quality SAKI 3Di Series

Precision and stability:

The equipment adopts a closed-loop dual servo motor drive system, a high-resolution linear scale, and a rigid gantry structure, providing unparalleled measurement accuracy and repeatability, suitable for absolute measurement requirements of PCBA, and ensuring the reliability of test results.

Efficient image capture:

The top camera is equipped with a CoaXPress interface, and the image capture speed is 1.7 times faster than the previous generation. It also provides three resolution options of 7μm, 12μm, and 18μm, which can flexibly meet various application scenarios and significantly improve detection efficiency.

Intelligent programming function:

The self-programming function of the quality SAKI 3Di Series is based on the concept of "no board, no skills, no pressure", combined with a powerful database and BOM data, and automatically creates accurate SPI and AOI inspection libraries, which can adapt to about 300,000 components, greatly reducing the difficulty of the operation and improving production efficiency.

| Model | SAKI3Di-LS2 | SAKI 3Di-LD2 | SAKI 3Di-ZS2 |

| Dimensions | L Single lane | L Dual lane | XL Single lane |

| Size(W)*(D)*(H)(mm) | 1040 × 1440 × 1500 | 1040 × 1440 × 1500 | 1340×1440×1500 |

| Weight | 900kg | 900kg | 900kg |

| Electric Power | Single Phase - 200-240V+/-10%, 50/60Hz | ||

| Air Requirement | 0.5MPa, 5L/min(ANR) | ||

| PCB Size(mm) | |||

| 7μm camera head | 50×60~330×330 | 50×60~330×330(Single mode) 50×60~320×330(Dual mode) | 50×60~686×870 |

| 12/18μm camera head | 50×60~500×510 | 50×60~500×510(Single mode) 50×60~320×510(Dual mode) | |

| PCB Clearance(Top) | 40mm | 40mm | 40mm |

| PCB Clearance(Bottom) | 60mm | 50mm | 60mm |

: next page