Zimbabwe MV-9

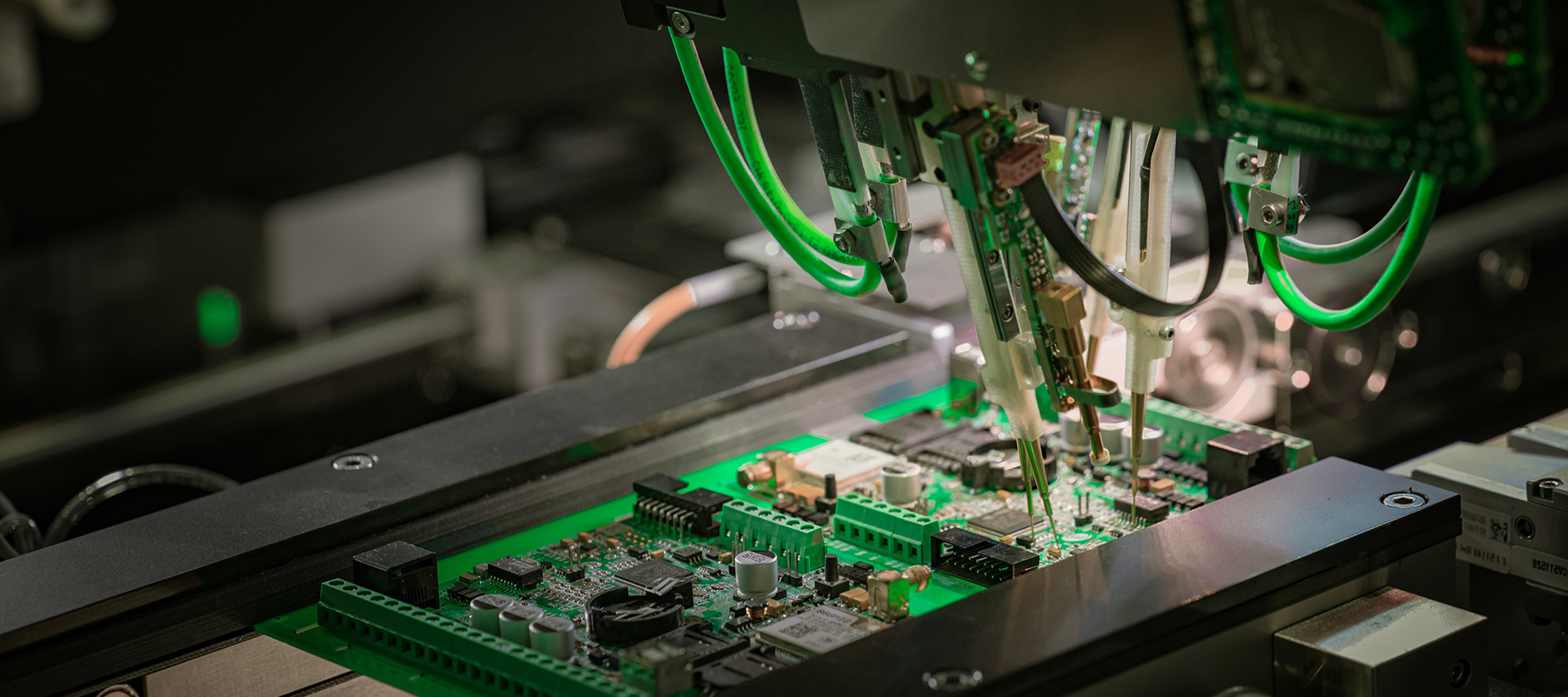

The MV-9 Series represents the pinnacle of full 3D AOI, offering unparalleled precision. It utilizes non-blind spot digital 12 projection moiré 3D inspection technology, ensuring comprehensive and accurate inspection. The system excels at inspecting diffused reflection components, OCR, and micro cracks with precision, thanks to its 8-phase coaxial color lighting.

Equipped with a 25-megapixel 7.7um CXP main camera, the MV-9 Series can inspect the smallest components with remarkable detail. Additionally, it features a high-resolution 18-megapixel angled camera system, further enhancing its inspection capabilities. This combination of advanced imaging technologies ensures the highest yield through precise inspection.

The MV-9 Series incorporates Side-Viewer® technology, enabling simultaneous five-dimensional inspection using 18-megapixel angled cameras. This system ensures no detail is overlooked. Intellisys®, the total process management system, enhances productivity and supports the implementation of smart factory principles. The AI Auto Programming feature simplifies programming by using an IPC international standard library, making it user-friendly and efficient.

Designed to be applied to both SMT production lines and the second process of semiconductor manufacturing, the MV-9 Series is a powerful 3D AOI solution. By combining full 3D inspection, full 2D inspection, and deep learning algorithms, it delivers the best yield and precise inspection results, setting a new standard for quality and efficiency in the industry.

Category:

ZimbabweMV-9

Product Description

| Model | MIRTEC MV-9 Series 3D AOI |

| PCB Inspection Area | |

| MV-9 | 50 mm x 50 mm to 510 mm x 460 mm |

| PCB Indexing Mode: 50 mm x 50 mm to 1,020 mm x 460 mm | |

| MV-9U | 60 mm x 60 mm to 660 mm x 610 mm |

| PCB Indexing Mode: 60 mm x 60 mm to 1,320 mm x 610 mm | |

| MV-9DL OMNI (Dual Lane) | Single Lane: 50 mm x 50 mm to 460 mm x 590 mm |

| Dual Lane: 50 mm x 50 mm to 460 mm x 300 mm | |

| Vision System (FOV Size) | |

| 15MP CoaXPress: (3,904 x 3,904 @ 120 fps) | Pixel Resolution(15 um): 58.56 mm x 58.56 mm (2.31” x 2.31”) |

| Pixel Resolution(10 um): 39.04 mm x 39.04 mm (1.54” x 1.54”) | |

| 25MP CoaXPress: (5,120 x 5,120 @ 72 fps) | Pixel Resolution(7.7 um): 39.42 mm x 39.42 mm (1.55” x 1.55”) |

| OMNI-VISION® Inspection Technology | |

| 3D Inspection | Digital Tri-Frequency Moiré Technology - 12 Projection Blue DLP |

| 2D Inspection | 15MP / 25MP CoaXPress Camera System |

| Max. 3D Inspection Height | 25 mm @ ±3 um |

| Additional Specifications | |

| Lighting System | Eight Phase Color Lighting |

| PCB Surface Clearance(Top) | 45mm |

| PCB Surface Clearance(Bottom) | 50mm |

| PCB Edge Clearance(Top) | 3mm |

| PCB Edge Clearance(Bottom) | 3.5mm |

| Max. PCB Warpage | ±2 mm |

| Max. PCB Weight | 4Kg |

| PCB Thickness | Standard: 0.5 mm - 3 mm / Optional: 0.5 mm - 5 mm |

| Min. Component Inspection | 0402 Chip (mm) / 01005 Chip (in) / 0.3 Pitch (mm) |

| Power Requirements | Single Phase 200~240V 50~60Hz; 1.1 KW |

| Air Requirements | 0.5 Mpa |

| Dimensions and Weight | |

| MV-9 | 1,250 mm L x 1,500 mm D x 1,600 mm H, Approx. 1,200Kg |

| MV-9U | 1,400 mm L x 1,650 mm D x 1,600 mm H, Approx. 1,500Kg |

| MV-9DL | 1,250 mm L x 1,500 mm D x 1,600 mm H, Approx. 1,400Kg |

: next page