Republic of Vanuatu MV-6 OMNI

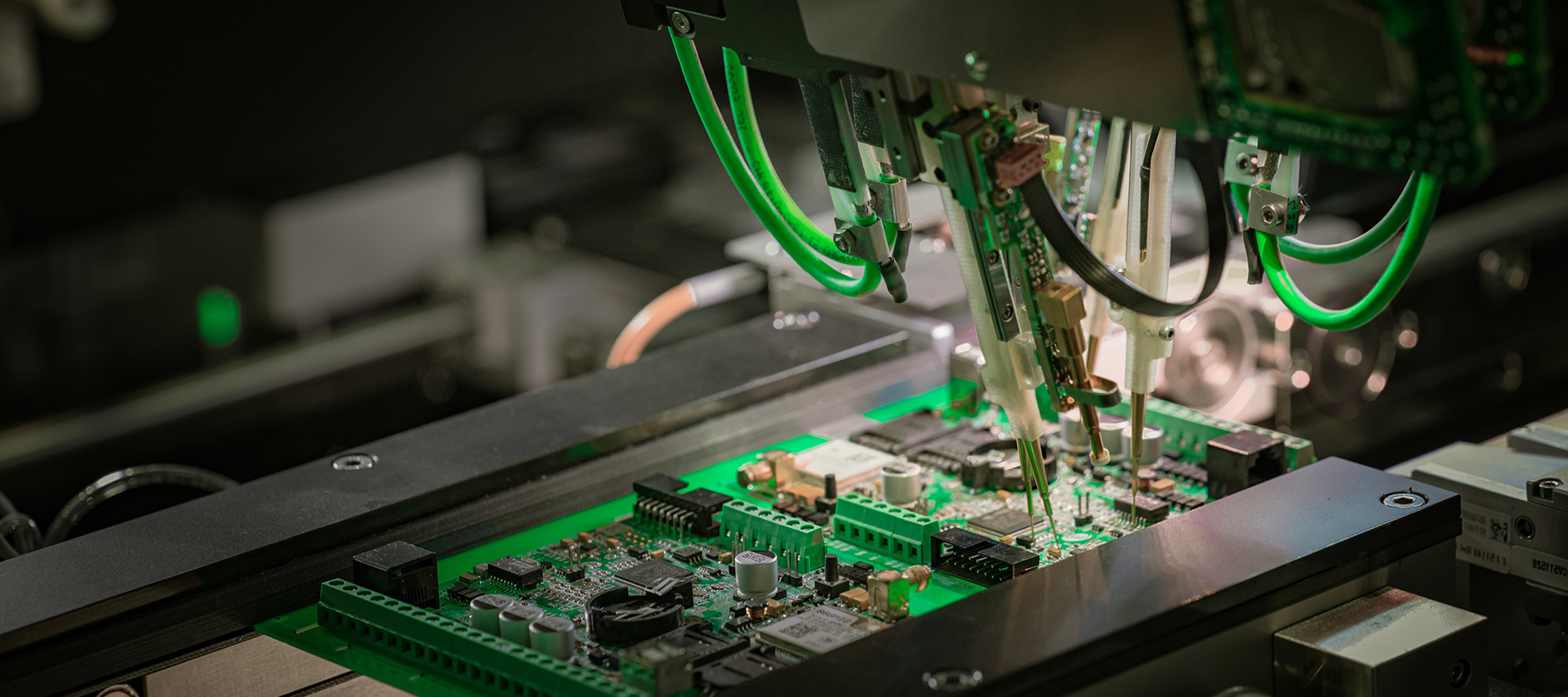

The MV-6 OMNI Series offers the world’s best performance in 3D AOI, designed to significantly enhance productivity. This system employs non-blind spot digital 12 projection moiré 3D inspection technology, ensuring comprehensive coverage and accuracy. It excels in inspecting reflective objects, OCR, and crack defects precisely, utilizing an 8-phase coaxial color light.

Equipped with an ultra-high-resolution camera and lens, the MV-6 OMNI Series can inspect the smallest components with exceptional detail. It also features an 18-megapixel angled camera that matches the resolution of the main camera, providing high-quality imaging from multiple perspectives.

The inspection speed increases by 45% when Turbo Speed is applied, making it highly efficient. The MV-6 OMNI combines full 3D inspection, full 2D inspection, and deep learning algorithms to deliver the best yield and precise inspection results. Its Side-Viewer® technology enables simultaneous 5-dimension inspection using 18-megapixel angled cameras, ensuring no detail is missed.

The Intellisys® total process management system enhances productivity and supports the realization of a smart factory. AI Auto Programming simplifies and streamlines programming using an IPC international standard library, making the process quick and user-friendly.

Offering the best performance at a reasonable price, the MV-6 OMNI Series stands out as an optimal solution for advanced 3D AOI, combining cutting-edge technology with practical features to improve overall manufacturing efficiency and quality.

Category:

Republic of VanuatuMV-6 OMNI

Product Description

| Model | MIRTEC MV-6e OMNI | MIRTEC MV-6em OMNI | MIRTEC MV-6DL OMNI |

| Max PCB Size Range | |||

| In-line AOI | 50 x 50 ~ 510 x 460mm | 50 x 50 ~ 330 x 280mm | 50 x 50 ~ 490 x 300mm (D) 50 x 50 ~ 490 x 590mm (S) |

| OMNI-VISION® 3D / 2D Inspection Technology | |||

| 3D Inspection Technology | Digital 8 Projection Moiré Technology | ||

| Height Accuracy | ±3μm | ||

| 3D / 2D Maximum Inspection Speed | |||

| 25 Megapixel Camera- 7.7μm | 1,460mm2 /Sec | ||

| 15 Megapixel Camera- 15μm | 4260mm2 /Sec | ||

| 15 Megapixel Camera- 10μm | 1890mm2 /Sec | ||

| 2D Maximum Inspection Speed | |||

| 25 Megapixel Camera- 7.7μm | 4593mm2 /Sec | ||

| 15 Megapixel Camera- 15μm | 10716mm2 /Sec | ||

| 15 Megapixel Camera- 10μm | 5080mm2 /Sec | ||

| System Specification | |||

| Lighting System | 8 Phase Coaxial Color Lighting System | ||

| PCB Top Side Clearance | 45mm | ||

| PCB Bottom Side Clearance | 50mm | ||

| PCB Thickness | 0.5mm ~ 3mm; 0.5mm ~ 5mm(OPTIONAL) | ||

| Maximum PCB Weight | 4kg | ||

| Minimum Measurement Size | |||

| 7.7 μm | 03015 (mm) / 0.3 Pitch (mm) | ||

| 15 μm | 0603 Chip (mm) / 0201 Chip (inch) / 0.4 Pitch (mm) | ||

| 10 μm | 03015 (mm) / 0.3 Pitch (mm) | ||

| Power Requirements | Single Phase(s) 200~240V 50~60Hz, 1.1 KW | ||

| Air Requirements | 5 Kgf / cm2 (0.5 MPa) | ||

| Dimension (mm) | 1,080(W) x 1,470(D) x 1,560(H) | 900(W) x 1,290(D) x 1,560(H) | 1,080(W) x 1,610(D) x 1,560(H) |

| Weight | Approx. 950 Kg | Approx. 870 Kg | Approx. 1,010 Kg |