With over 15 years of industry experience, our commitment to innovation and precision goes beyond offering cutting-edge solutions – we prioritize your satisfaction.

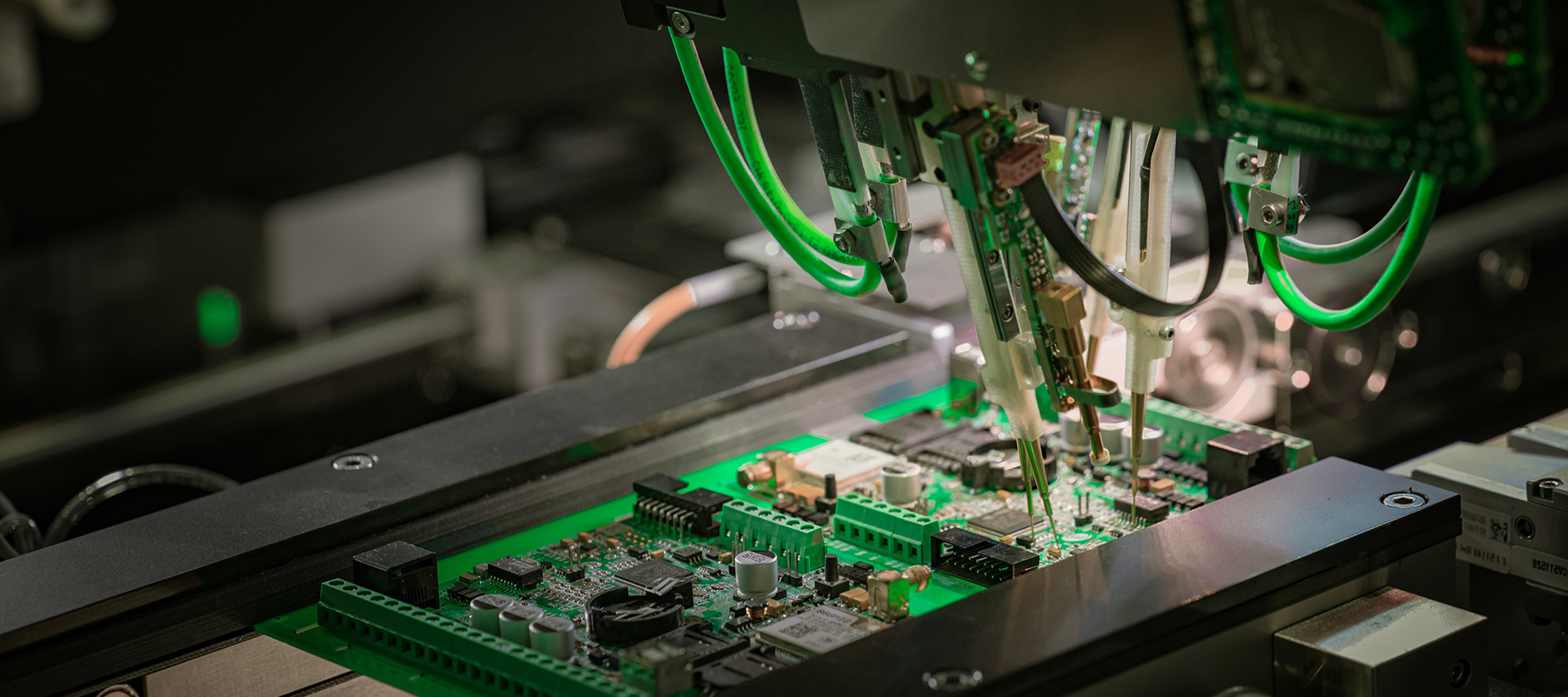

The KOH YOUNG Zenith AOI Series is the only machine that offers True 3D Inspection, effectively addressing issues caused by highly specular packages and shadows from adjacent parts. Utilizing patented True 3D technology, the Zenith measures true profilometric component shapes, including foreign materials, patterns, and solder joints, to overcome inspection challenges. Uniquely, the Zenith AOI Series sets its inspection criteria based on IPC-610 standards for electronic assembly acceptability. It provides clear and precise AOI measurements to accurately identify a variety of defects, such as missing solder, offset, polarity issues, upside-down components, OCV/OCR, solder fillet problems, billboarding, lifted leads, lifted bodies, tombstones, bridging, and more. With its quantitative True 3D measurement-based approach, the system ensures exceptional accuracy and repeatability. Leveraging Koh Young’s proprietary vision algorithms, the Zenith Series can quantify the exact height of a solder joint. Even in the presence of shadows or interreflection challenges, the Zenith performs accurate inspections and measurements according to IPC-610 standards for electronic assembly acceptability.

Koh Young Zenith 2 is pioneering AOI systems with innovative SMT process management tools by combining advanced vision algorithms with high-resolution optics, enabling broader inspection coverage, including advanced tall component inspection. The Zenith 2 provides clear and precise AOI measurements to accurately identify multiple defects such as missing solder, offset, polarity issues, upside-down components, OCV/OCR errors, solder fillet problems, billboarding, lifted leads, lifted bodies, tombstones, bridging, and more. Its powerful side-view camera option quickly identifies, measures, and analyzes potential defects on hidden or obscured components. Traditionally, AOIs faced challenges measuring shorter components near taller parts due to shadow effects. The Zenith 2 overcomes these challenges by incorporating a multi-projection Moiré interferometry system, allowing it to handle components up to 25mm tall. The cutting-edge Zenith 2 AOI incorporates patented mechatronic technology, positioning it as the ultimate AOI solution. Its Self-Diagnosis feature enables operators to take precautionary measures through predictive maintenance, reducing process interruptions, enhancing equipment uptime, and ensuring optimal machine performance. The Self-Diagnosis feature includes distinct modules for periodical machine check-ups on critical items such as 3D/2D light intensity, PZT feed, height accuracy, and XY offset.

As the true 3D AOI system, KOH YOUNG ZENITH LiTE effectively measures solder joints and components in 3D, perfectly combining traditional 2D inspection with true 3D measurement, making inspection according to IPC-A-610 attainable. ZENITH LiTE has the capability to make clear and concise 'go-or-no-go' decisions for solder joint inspections, detecting a wide range of potential defects including missing solder, offset, rotation, polarity, upside down, OCV/OCR, solder fillet, billboarding, lifted lead, lifted body, tombstone, bridging, and more. Koh Young’s unique Warp Compensation provides a revolutionary solution to PCB warpage. Utilizing its exclusive 3D imaging and algorithms, the Zenith LiTE minimizes false calls regardless of harsh PCB environments, including FPCB, slope, height differences, local board warp, rotation, shrinkage, and expansion. Zenith LiTE’s intuitive interface simplifies setup, reducing programming time for package registration and setting inspection conditions. The evaluation benchmark can be easily managed by an operator, streamlining and speeding up programming, while also making identification universal.

The MV-6 OMNI Series offers the world’s best performance in 3D AOI, designed to significantly enhance productivity. This system employs non-blind spot digital 12 projection moiré 3D inspection technology, ensuring comprehensive coverage and accuracy. It excels in inspecting reflective objects, OCR, and crack defects precisely, utilizing an 8-phase coaxial color light. Equipped with an ultra-high-resolution camera and lens, the MV-6 OMNI Series can inspect the smallest components with exceptional detail. It also features an 18-megapixel angled camera that matches the resolution of the main camera, providing high-quality imaging from multiple perspectives. The inspection speed increases by 45% when Turbo Speed is applied, making it highly efficient. The MV-6 OMNI combines full 3D inspection, full 2D inspection, and deep learning algorithms to deliver the best yield and precise inspection results. Its Side-Viewer® technology enables simultaneous 5-dimension inspection using 18-megapixel angled cameras, ensuring no detail is missed. The Intellisys® total process management system enhances productivity and supports the realization of a smart factory. AI Auto Programming simplifies and streamlines programming using an IPC international standard library, making the process quick and user-friendly. Offering the best performance at a reasonable price, the MV-6 OMNI Series stands out as an optimal solution for advanced 3D AOI, combining cutting-edge technology with practical features to improve overall manufacturing efficiency and quality.

The MV-7 OMNI 3D AOI Series comes equipped with an Intel® Multi-Core PC, a 32” flat screen LCD monitor, and runs on Windows 10™ OS. It includes an HDD, mouse, keyboard, and a network LAN card for seamless connectivity. Utilizing OMNI-VISION® technology, the system features digital tri-frequency moiré technology with 12 projection blue DLP, offering a 25mm 3D inspection capability. This ensures precise and comprehensive inspection of components. The system boasts a three-stage high-speed conveyor with programmable width control and automatic PCB support, enhancing operational efficiency. Its advanced eight-phase color LED lighting system further ensures detailed and accurate inspection by providing optimal illumination. Capable of both pre and post-reflow inspection, the MV-7 OMNI offers versatility in the inspection process. Automatic programming is made easy with the Automatic Teach Tool (ATT) software, which uses centroid data to streamline setup. The comprehensive package type library simplifies component programming with a drag-and-drop interface, making it user-friendly. Additionally, the MV-7 OMNI includes local system software such as Repair Plus Software and Statistical Process Control (SPC) Software, providing robust tools for process improvement and quality control.